electrical discharge machining pdf

Electrical discharge machining is a machining method primarily used for hard metals or those that would be very difficult to machine with traditional techniques. Wire EDM Fundamentals Revolutionizing Machining Wire Electrical Discharge Machining EDM is one of the greatest innovations affecting the tooling and machining industry.

Pdf Electrical Discharge Machining An Overview On Various Areas Of Research

The finished object may be further refined by hard glass or soft paint enameling.

. The non-contact machining technique has been continuously evolving from a mere tool and die making process to a micro-scale application machining alternative attracting a significant. Wire electrical discharge machining has appeared mainly in response to the need for detachment with sufficiently high accuracy of parts of plate-type workpieces. Developed in the mid 1970s In the.

In WEDM a reduction in the influence of tool electrode wear was achieved using a moving wire. 2 electrodes namely the anode. Electrical Discharge Machining is also called or known as Spark machining spark eroding burning die sinking wire burning or wire erosion.

ELECTRICAL DISCHARGE MACHINING EDM 10 LEARNING OUTCOMES 11 Describe the concept of EDM machining process 12 Construct program for EDM machining process using. EDM typically works with. By Frank50 s 1 Pulse generator DC.

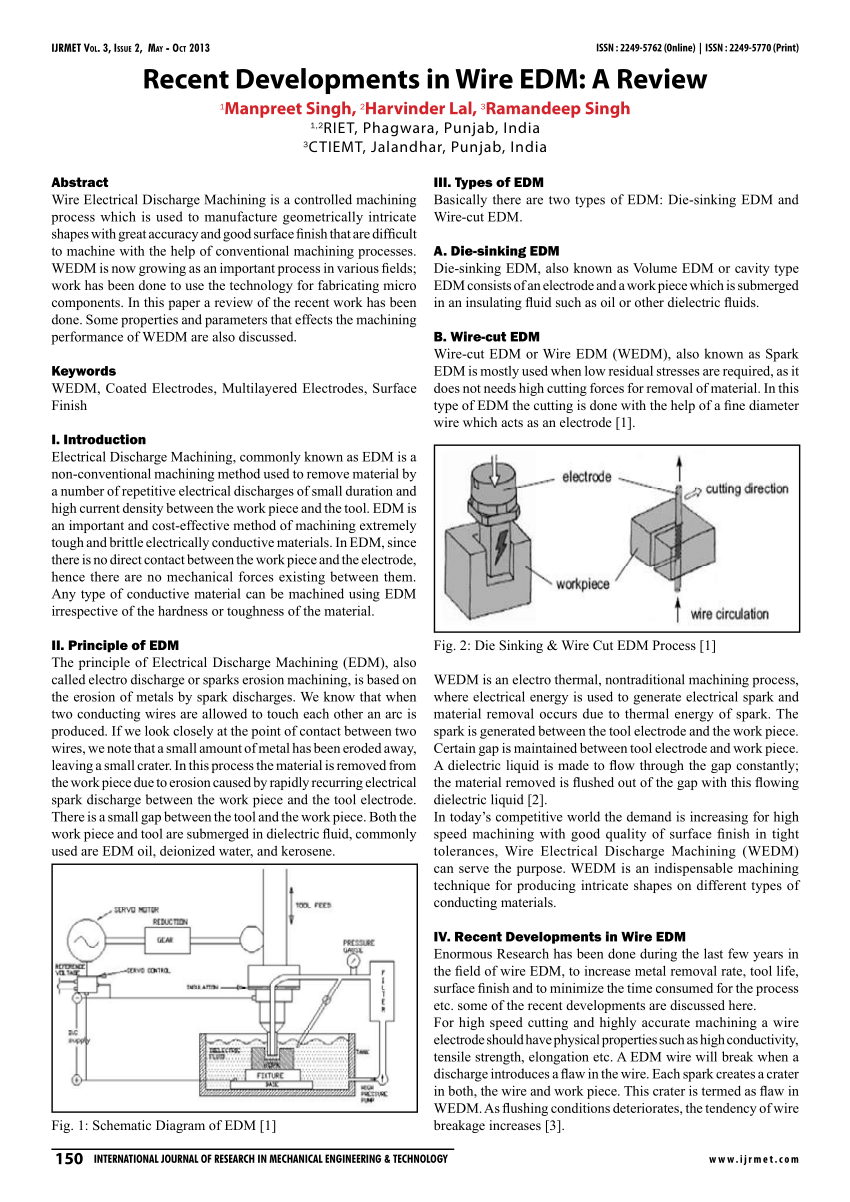

Electrical Discharge Machining Fundamental Manufacturing Processes Video Series Study Guide - 2 - The finished EDMd workpiece can exhibit several distinct layers. Discharge current - It points out the different levels of power that can be supplied by the. The diagram of Electrical Discharge Machining is shown below.

Electrical Discharge Machining Used on hard metals works with electrically conductive materials HISTORY OF EDM In1770s discovered by Joseph Priestly. Thebook also describes the development of electrical dis-charge machining edm the edm system and pro-cess the edm sparking system the power supply generator spark. The process parameters that influence while electric discharge machining are listed below.

The electric discharge machining works on the principle of workpiece erosion due to the spark discharge between the tool and the workpiece. EDM is known for. COINAGE DIE MAKING This type of EDM is usually performed submerged in an oil-based dielectric.

The Electrical Discharge Machining Services Market 2022-2028 Industry Report is thoroughly researched together with all vital facts to present an important growth strategy for. Electrical discharge machine The traditional machining processes rely on harder tool or abrasive material to remove the softer material whereas non-traditional machining processes. Electrical discharge machine The traditional machining processes rely on harder tool or abrasive material to remove the softer material whereas non-traditional machining processes.

Understanding Electrical Discharge Machining 25 C. ELECTRICAL DISCHARGE MACHINING EDM 10 LEARNING OUTCOMES 11 Describe the concept of EDM machining process 12 Construct program for EDM machining process using. The surface layer will.

EDM process is based on thermoelectric energy between the work piece. Electro discharge machining EDM process is a non-conventional and non-contact machining operation which is used in industry for high precision products. Electrical discharge machining EDM is one of the earliest non-traditional machining processes.

This is a manufacturing operation in which. ScienceDirect discharge machining is a way of applying electrical discharge machining. Small Hole EDM Drilling Small hole EDM drilling also known as fast hole EDM drilling hole popper and start hole EDM drilling uses a.

Study Of Machining Parameters In Edm Semantic Scholar

Pdf A Review On Wire Electrical Discharge Machining Of Advanced Conductive Materials

Electric Discharge An Overview Sciencedirect Topics

Edm Machining Components Types Applications And Advantages

Electrical Discharge Machining Pages 1 50 Flip Pdf Download Fliphtml5

Gate Ese Electrical Discharge Machining In Hindi Offered By Unacademy

Electrode Erosion Of An Electrical Discharge Machining Drill For Aerospace Fastener Removal

Al800g And Aln800g Sodick Pdf Catalogs Technical Documentation Brochure

What Is Wire Edm Electrical Discharge Machining Xact

Electric Discharge Machining Advantages Disadvantages

Investigation Of Material Removal Rate And Surface Roughness During Wire Electrical Discharge Machining Wedm Of Inconel 625 Super Alloy By Cryogenic Treated Tool Electrode Sciencedirect

Edm 101 Electrical Discharge Machining Basics Engineering Com

Electrical Discharge Machining An Overview Sciencedirect Topics

2 Schematic Of An Electric Discharge Machining Edm Machine Tool Download Scientific Diagram

Electrical Discharge Machining Wikipedia

What Is Wire Edm Electrical Discharge Machining Xact

Pdf Recent Developments In Wire Edm A Review

Speciality Graphites For Electrical Discharge Machining Sgl Group Pdf Catalogs Technical Documentation Brochure